|

|

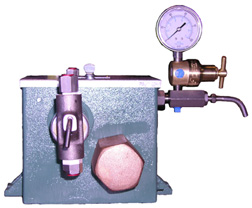

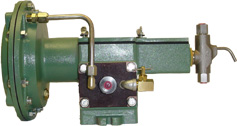

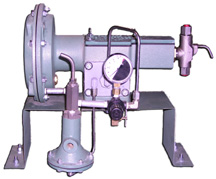

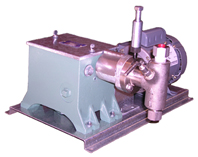

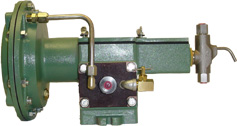

Flomore's gas driven 5200 Series Injector utilizes a molded diaphragm to drive a piston through chevron packing making it a positive displacement pump capable of discharge pressures of 6,500 PSIG.

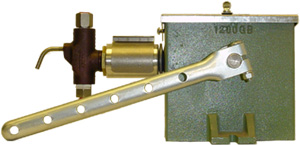

A simple rotary switching valve (B-0446) directs the incoming operating gas (35 PSI MAX) behind the diaphragm (C-0290) which causes the pump to stroke forward. The valve then shuts off the inlet gas and opens to exhaust the spent gas behind the diaphragm, a large spring returns the diaphragm and the sequence begins again.

A choice of three plunger sizes, two stroke lengths and controllable strokes per minute with an optional slow speed controller allows a wide range of volumes to be pumped, from less than a quart to 30 gallons per day.

The oil impregnated bronze bushing (not in contact with gas supply) extends the life of the thrust rod and protects the pump housing. This, combined with the enclosed and pre-lubricated flipper arm bearing, insures continued operation in the event oil is not added to the oil reservoir.

Sour gas trim is standard and is furnished on all models except those using the optional slow speed controller. The standard fluid end is ductile iron with stainless trim and plunger, and stainless is availiable as an option.

APPLICATION:

1. The introduction of de-emulsifiers, solvents, corrosion inhibitors, de-scaling agents and oxygen scavengers.

2. Water treatment

3. Injection of methanol in gas pipelines

4. Injection of surfactant (soap) into low pressure gas wells with high water content

|